Description

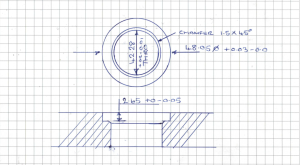

If you would like to sleeve your own casing we can supply the steel bush.

We would suggest an interference fit of 0.02mm and also use ‘bearing fit’ or similar.

If you are purchasing a rebuilt LT230 and would like to upgrade to a ‘Sleeved Casing’ please see information on this below:

The hole that supports the head of the intermediate pin in the LT230 casing is prone to wearing, and the pin elongates the hole so that it is out of round.

This can lead to a transfer case whine, and an oil leak.

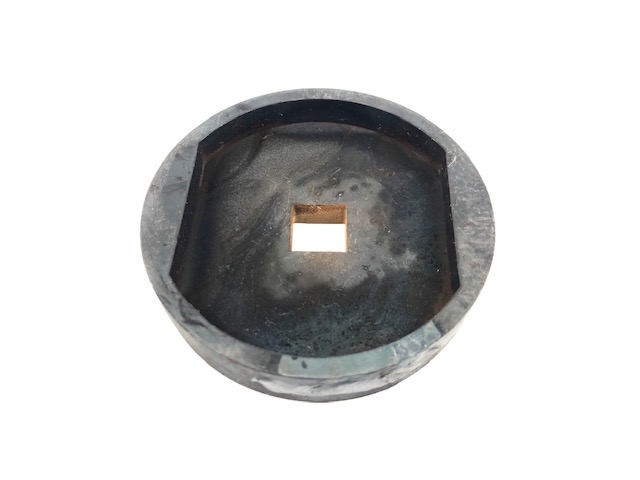

Using our CNC lathe, we turn a stepped bush from EN24T steel. We mount the casing in our CNC mill, and machine an oversized hole on the correct centre and press the steel bush into the housing.

This will now have a longer life than the original housing, as the pin is now supported in the steel bush.

Please see photos below:

*Click on the image to enlarge

GREGORY FENECH (verified owner) –

I am rebuilting a TOP quality Lt230 for my TD5 complete with ATB diff and fitted one of these sleves to make sure to eliminate leaks and extend the life of my case. Less than an hour on the milling machine and its done.

davidlawrence (verified owner) –

This product is the best in the market I rebuild 15+ lt230s a year and have seen many different types , this is the only bush I would use