Description

This model is to suit the P38 Range Rover and the 2002 onwards 110 rear axle.

The Locker includes a new pair of Timken journal bearings.

We can supply the Ashcroft Locker as individual units or we can build them into diff casings for you. Whatever spec you require, whether it be diff “pegging”, standard 3.54 ratio or one of our HD different ratios, we can build them to your needs. If you would like a complete rebuilt diff please see here

Please note that if you opt to have your locker turned there may be a small delay in dispatch of the order

Note we can fit the locker to your diff assuming it’s in good condition, please enquire for pricing.

Please note that you will need to drill and tap a hole in the diff housing for the air feed pipe to pass through. We are able to supply the drill and tap should you require.

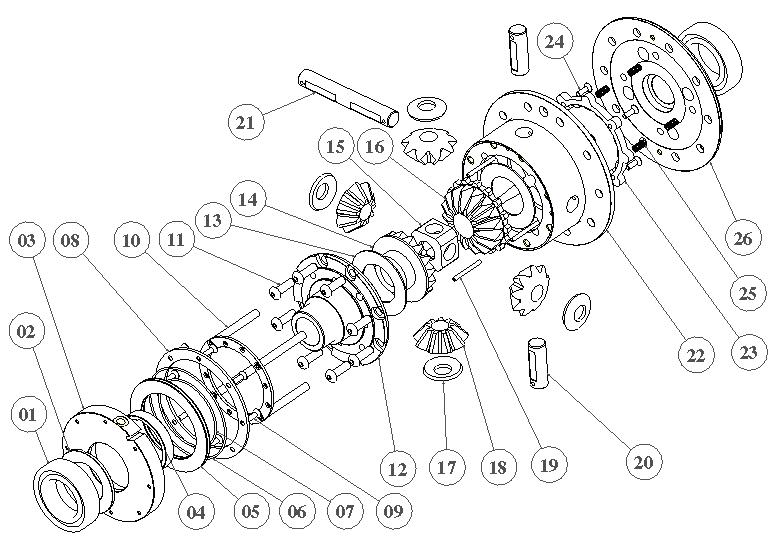

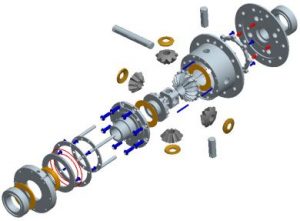

We are able to offer a complete spare parts listing. Please see the exploded diagram below to help identify which parts you may require.

Spare parts are listed in our product codes ASH-AL01 to ASH-AL-42

Concept

There are many types of lockers available for Landrover vehicles but all seem to have a weak point or Achilles heel, so we set out to design a locker from a blank canvas to be cost effective, strong and without the weaknesses of other designs.

Design

We wanted a selectable locker which would fit into the rover diff casing with minimal installation work, i.e, without mods to the axle housing. We looked at electric and pneumatic activation and decided pneumatic was preferable for reliability and simplicity. One of the key requirements for our design was zero air leaks as this is one of the main issues with other air operated lockers. To achieve this we opted for a static piston rather than the rotating seal used on other air lockers, which was prone to leaks. We also wanted to ensure we had a full 6mm of engagement when locked as other air lockers have just 2.5mm and are prone to slipping out of lock when loaded.

The final design settled on a 4 pin diff centre; one of the diff side gears has an outer ring of dog teeth around it which a locking collar engage with when locked, thus locking collar is on the crown wheel side, the locking collar is held with 4 pins which pass through the diff centre on the non crown wheel side . Outside the diff centre the 4 pins are peened to a steel thrust ring, this assembly forms a robust all steel ‘cage’, not plastic like other designs which were prone to failing.

On the non crown wheel side inside the journal end cap is a cylinder in which sits a bronze piston, the piston has a groove around the inside and outside diameters which O rings sit in. Once the piston is fitted a retaining ring is bolted around the end of the cylinder to stop the piston coming out, air is fed to the cylinder through a copper pipe to a 90 deg compression fitting which fits to the outside diameter of the cylinder. When air is applied the piston moves along the cylinder until it reaches the retaining ring, it does not spin in the cylinder, the cylinder is static and sits on a bronze bush at the side of the diff centre. Inside the journal bearing on the cylinder side is a bronze thrust ring to hold the cylinder. A locking tab is fitted to one of the journal end cap bolts and locates in a cut out in the cylinder to stop it rotating.

The copper air feed pipe goes from the side of the cylinder through the diff housing, it doesn’t have to pass over the crown wheel.

The lockers are assembled on our premises and supplied with switch (front and rear fascias), solenoid, air line and all required fittings, excludes air compressor.

We have used 6mm pneumatic push fit fitting to the locker as we have found that other air lockers that have threaded fitting and hoses will either tear a pipe or break a fitting if the air line gets snagged on a branch etc, our locker uses these pneumatic ‘push fit’ fittings which will still get snagged but just pull out so you just need to push back in to fix rather than having to replace hoses etc.

Operation

When air is applied, the static annular piston moves across and pushes the spinning thrust collar which slide the 4 pins and move the locking collar over the side gear teeth to lock the diff, the diff is unlocked when the air pressure is released and 4 return springs push the locking collar out of engagement with the side gear. These diffs need 75-100 Psi to operate.

Materials

Whilst we want the unit to be cost effective, the strength is paramount, all steel parts are turned from billet UK spec EN24T, Gears are 8620, locking collar is 300M.

Key features :

Full 6mm of locking collar engagement

Static annular piston, minimises risk of air leaks

Large diameter piston gives a 55% increase of hold in force over competitors

High spec materials throughout

Competitively priced

2 year warranty

The Ashcroft Locker has been tested in two competition vehicles before being launched for public sale with zero failures and the following results:-

Mamby September 2010 1st

Hound of the Baskervilles November 2010 1st

Santa’s Challenge December 2010 1st

Muddy Truckers March 2011 1st

Croatia Trophy May 2011 1st

Vehicles driven by Jim Marsden, Gigglepin 4 x 4 and Steve Gittens ~ our thanks to them for testing our locker.

Diff Pegging This is an option for those customers who are fitting their Locker to a pegged diff. It is not an adviseable option if the Locker is being fitted to a standard diff. If you are pegging the diff the outside diameter must be reduced to clear the pegging pad. If you do this op and then fit to a standard, non pegged diff, the Locker will be weaker . For more information on pegged diffs please see here

Please note if you opt to have a turned locker then there may be a small delay in dispatch of your order

User Guide

The locker can be engaged in theory at anytime that you have zero wheel speed difference, ie at a standstill or driving in a straight line but we would advise only locking below 20 mph due to handling considerations. Do not lock when you have a high difference in wheel speed ie when stuck and wheelspinning. When engaged you can expect it to lock in under 2 seconds, unlocking may take 3-5 seconds depending if the lockring is undertension due to ‘wind up’. Beware of crossing side slopes with the locker engaged as this may encourage the rear to swing downhill.

Joël Delhoste (verified owner) –

Petite modification sur l’avis que j’ai laissé , il n’est pas possible de monter des vis d’origine Land Rover pour fixer la couronne , elles sont trop courtes , donc vous êtes obligés de mettre les vis fournies avec le kit. Le perçage et taraudage à 1/4 BSP du carte ne pose pas de problème particulier . J’ai du meuler un peu le carter pour permettre le passage des tête de vis Chc (vis BTR) car ces dernières touchaient légèrement la fonderie du carter. Sinon tout e fait très facilement.